VHA CH for comfort cooling: a new range with screw compressors, full inverter and HFO

Efficiency, sustainability and health

When we talk about HVAC systems for comfort cooling, we are faced with a fairly complex and heterogeneous scenario. Hospitals, cinemas, offices, shopping centers have different characteristics but also common needs. For example, energy consumption, in addition to lighting, is largely (about 60%) spent on cooling and heating systems. It is therefore evident how important it is to rely on HVAC systems that offer high efficiency performance.

But that is not all. Recent research conducted by the University of Cambridge reveals a close relationship between the sustainability of buildings and their financial performance. This adds to other studies that demonstrate the correlation between sustainability and the health of those who work or live in so-called “green” buildings (just think of factors such as air quality, hygiene, less exposure to allergens, greater productivity, etc.).

This is why in such a complex landscape, HVAC systems must be designed with the utmost attention and customized to meet specific requirements and to ensure the best performance and environmental conditions.

The new range

To meet these needs, we have designed a new series of air-cooled chillers with full inverter screw compressors, characterized by the use of HFO-1234ze.

This new range is fully compliant with ERP2021 requirements and has a cooling capacity range from 500 to 1500 kW.

The operating limits in standard configuration range from -10 to +46 ° C but thanks to the customized control logics they can be brought from -15 to +50 ° C. And all this while ensuring high levels of energy efficiency, with EER values up to 3.07 and ESEER up to 5.02 (W / W).

Reliable and long-lasting technology

Screw compressors have the advantage of having a simple structure, made up of few moving parts that allow a continuous and fluid motion. This means a decrease in mechanical stress and therefore greater reliability over time and a reduction in maintenance costs. Furthermore, the simplicity of this engineering ensures a considerable reduction in mechanical vibrations and related noise, with consequent advantages in terms of comfort.

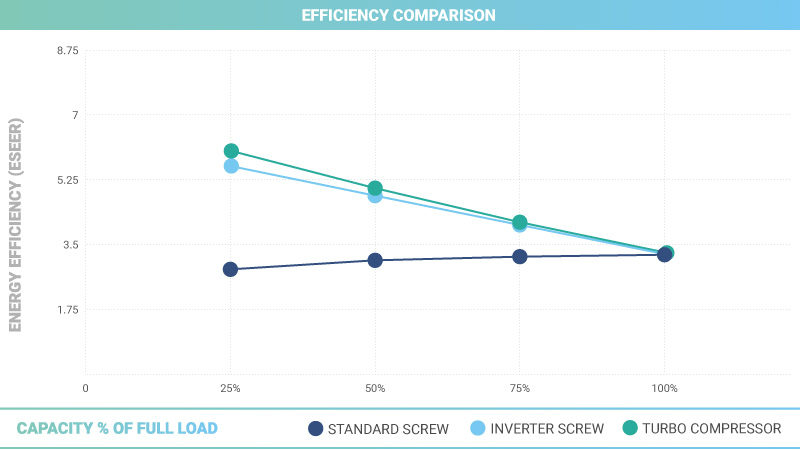

In the full inverter configuration, the performance in terms of energy efficiency is comparable to that of turbine compressors (see table below) because the inverter adapts the compressor’s cooling capacity to the needs of the system and, moreover, requires a very high starting current. lower. The result is a huge benefit in terms of efficiency and energy savings.

A “green” choice

Over the years, our industry has become more and more aware of how important it is to adopt green technologies on a large scale. This is why we try to favor, where possible, the use of low GWP refrigerants. The HFO-1234ze represents a very innovative technology in this sense. In addition to being the “greenest” refrigerant available on the market (GWP <1 *), it is extremely efficient and this represents a further advantage compared to the reduced impact of direct emissions, also reducing indirect emissions and also guaranteeing significant savings on operating costs.

*According to IPCC “Climate Change 2013”