EcoSeries: a more sustainable and efficient solution

EcoSeries is our new series featuring air-cooled units covering a cooling capacity range from 200 to 600 kW and equipped with the new generation Danfoss DSG scroll compressors capable of using the most environmentally friendly refrigerant in the world: HFO-1234ze, classified as A2L according to ASHRAE 34.

EcoSeries is specifically designed for cooling large buildings, infrastructure projects, remote cooling/heating systems and other applications. We are convinced that it is a more efficient and sustainable alternative to screw compressor units of the same size.

Danfoss DSG scroll compressors

The next-generation DSG scroll compressors are specially designed for HFO-1234ze applications.

These compressors with scroll technology offer a high level of efficiency (EER) and reliability, maximum silence and an almost total absence of vibrations.

The compressors are equipped with a non-return valve on the discharge to prevent dangerous reflux of refrigerant when the compressor is not working, and with an internal overpressure safety valve to prevent dangerous and excessive differences of pressure, which may occur due to accidental causes. A thermostat – or equivalent sensor – provides protection against excessive discharge temperature; the electric engines are protected against the excessive temperatures of the coilers by sensors immersed in the electric motor.

Scroll compressors are characterized by:

- simple, lightweight and compact construction;

- large oil reserve;

- optimized scroll, motor and shell design;

- 100% suction gas cooled and shielded motor;

- large refrigerant capacity;

- operation with HFO-1234ze.

The main advantages deriving from the use of these new Danfoss compressors are represented, among others, by the easy installation and maintenance, by the high energy efficiency combined with the low noise level and by the ability to operate in high temperature environments.

HFO-1234ze

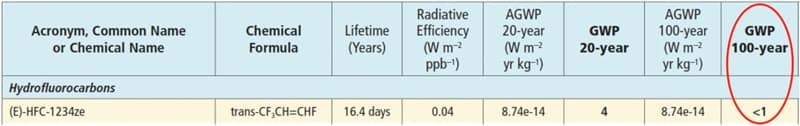

The HFOs maintain a high efficiency and at the same time significantly reduce the environmental impact, as their molecules decompose very quickly in the atmosphere, resulting in a very low GWP. Furthermore, these refrigerants have been classified A2L according to the ASHRAE 34 standard, i.e. non-toxic and mildly flammable. In fact, they need at least 1000 times more energy to ignite than hydrocarbons, and the burning velocity is so low that, in the event of ignition, the flame will spread very slowly and self-extinguish. These features make the HFOs a safe choice in a wide range of applications (refrigeration, air conditioning, heat pumps).

According to a 2015 IPCC report, the 100-year GWP of HFO-1234ze marketed by Honeywell is less than 1. Our choice, thus, was motivated by both ethical and commercial reasons. We are convinced, in fact, that if we consider all the technical requirements that a refrigerant gas must have today, the HFOs represent the best combination of performance, safety, costs and environmental benefits.