The correct multipurpose selection

The manufacturer, based on own experience and knowledge, can suggest some alternative or additional considerations that could help select the most suitable unit for the specific requirements of the project.

- Simultaneous loads: the multipurpose unit is born to satisfy a requirement whereby both a cooling and heading load are present. Each manufacturer will approach certain technical design difficulties, such as refrigerant migration during transitioning stages, the forced movement of the refrigerant, oil return and components selection and control, based on their own experience. The moving parts, which are integrated and interdependent during the various stages of operation, are quite many. All the above brings to the conclusion that the application is suitable and will maximize the efficiency and reliability of the product, when the unit is designed considering both cooling and heating loads for the majority of time of the unit’s life.

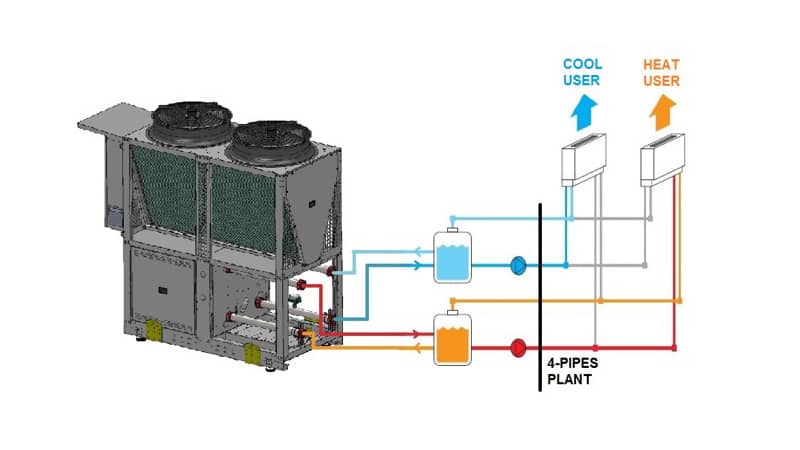

- Independent circuits: unlike heat pumps, where due to the common heat exchanger the advice is to maintain the same dT for both cooling and heating, in a 4-pipe system that is not an issue. The circuits for heating and cooling are independent, therefore the system can be optimized for

simultaneous loads and different dTs at the same time. - Selecting the unit based on the peak winter requirement: for a 4-pipe system, such a selection choice will have a severely adverse impact on the system. To assess this please note that all the points mentioned in the post dedicated to reversible heat pumps are still applicable, in addition to some considerations relevant to 4-pipe system units, explained as follows. In the operation of a 4-pipe system (heating + cooling) the gas will condensate via heat exchange with the water, so the fans will not be running. In this operating condition (MULTIPURPOSE) the unit is not affected by the external ambient temperature. This means that the unit will always work at conditions close to nominal. Therefore dimensioning the unit at peak winter condition will effectively increase the capacity and, in the majority of cases, will mean that the unit is reduntant compared to the effective load of the plant.

- Heating water flow and cooling water flow: given that oversizing the multipurpose unit will have a purely NEGATIVE effect on the system, we need to evaluate how this affects the energy consumption rates of the whole system. Multipurpose units, as explained above, need to constantly, and according to their own logic, operate a number of heat exchanges based on different states to prevent oil and refrigerant returns. This means that the pumps, both on heating and cooling circuits, have to always be ON and water flow needs to be always guaranteed (this also means that buffer tanks need to be considered accordingly as well). Pumps always ON means a constant power consumption needs to be considered, and if the unit is oversized, such power consumption will impact negatively on the system in a bigger fashion than in the case of reversible heat pumps, increasing overall system power consumption and impacting internal system safety. Such aspects, according to Hecoclima’s experience, are one of the most neglected by consultants, which translates in a chance to aid the selection of the most suitable unit, making the unit more efficient for the system and increasing the energy savings for the end user (power consumption, size of pumps, valves, piping, insulation, buffer tanks).

- Consideration of buffer tanks: the note mentioned for reversible heat pumps is still applicable. Moreover, if for heat pumps in certain cases operation without buffer tanks is acceptable, this is NEVER POSSIBLE with multipurpose units. This is why Hecoclima TDS always make available the information necessary to select the suitable buffer tank(s). Why? Because multipurpose units are regulated and calibrated according to timings that sometimes do not coincide with the timings of the plant (for example, a multipurpose unit is in cooling mode, and the plant sends a signal for

heating → this initiates a series of commands to the unit for various adjustments, which mean that the reaction time will not be immediate, therefore a buffer tank is needed to compensate; the same can be said if the system then stops requiring heating and sends a signal to go back to

cooling mode → the unit still has to complete the change of state, work in heating mode first, and then switch back to cooling mode). The unit timings not only involve a large number of components and controls, but are also set so that the priority is always to safeguard the unit and its inner

mechanisms: buffer thanks are therefore essential for these systems.

A word of advice from Hecoclima

- Selecting the unit based on the peak winter requirement: ALL the considerations made for reversible heat pumps are still valid. Hecoclima’s suggestion is regarding simultaneous loads: particular attention should always be dedicated to how the unit is selected (water flows, buffer tanks) and the first technical data that needs to be evaluated should be the design capacity (COOLING+HEATING).

- A suggestion for plant design: quite often manufacturers have to work with design limitations that seem quite improbable, such as unit selection at peak load or operation only in heating mode. Whenever the project engineer has already taken into account all of the manufacturer’s suggestions regarding how to select a multipurpose unit, but chooses to prioritize the critical aspects of the plant and satisfying the end user’s requirements at the most extreme conditions, we have an additional option. We can offer a plant solution whereby the multipurpose unit is designed according to our suggestions paired (meaning that the heating circuit is the same) with a heat pump that will only cover loads at extreme conditions (see suggestions for selection of reversible heat pumps). At this point, by reviewing the notes regarding the water flow requirements for a multipurpose unit, we can see that the solution multipurpose + heat pump allows to keep the heat pump water pump in OFF mode until there is actual heating load, reducing the ancillary costs when the load is close to zero (unit is OFF = pumps are OFF).

- Other possible options: the requirement for multipurpose units to produce hot water at very high temperatures is quite low. However, in cases where there is always (or very often) a cooling load, the unit can produce water at low temperature (heating mode) and use the same water to the condenser (via a buffer tank kept at 40/45 °C) for a booster with R134a (scroll compressors) which will then allow the water temperature to reach 75..80 °C.